Outsource Your Business Today!

Creative Concepts India is a product sourcing service that focuses on areas of item growth, timely deliveries, online & article manufacturing inspections, control & communication.

We source all apparels, accessories, gifts, assets, food as well as hard goods including furnishings, furnishings, lighting, home fabrics and also decorative devices. We aid our customers to comprehend the ever-changing worldwide market and discern their business needs.

We have know-how in all buying procedures including product design and development, inspecting resources, product top quality, manufacturing planning, and supply chain management.

Don’t Settle For Less

SOURCING

Sourcing

While online networks are a logical place to start researching manufacturers, it can be difficult to contact and communicate with suppliers you find on these websites.CCI has sourcing staff both in Moradabad & New Delhi that are experienced in communicating with suppliers in the region.

After working with you to clearly define your product requirements and other expectations, CCI will begin our search by using publicly available resources and attending trade shows as needed. then we'll contact prospective suppliers that can deliver your product.

When a select group of potential suppliers has been identified, CCI will review the strengths and weaknesses of each you. You'll receive a report of our findings, including a shortlist of capable suppliers. When one or more suppliers has been decided upon, you can continue to benefit by having our staff help mediate each stage of the relationship from sample requests, opening molds and PO placement.

We're different from other sourcing agents because we don't take any commissions for brokering trade deals. Instead, we'll bill you on an directly. We're here when you need us and maintain a high standard of integrity and privacy with each supplier and importer we work with.

Charge Forward

PRODUCT

DEVELOPMENT

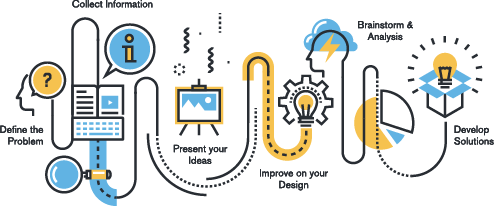

Product Development

This is the fun part. Product designers find inspiration everywhere – from art, architecture, nature and pretty much everywhere they go. What can start out as a sketch on a napkin in a restaurant, is eventually conceptualized and illustrated in a way that allows a manufacturer to create a prototype sample. Throughout the product development cycle, Sam, have input and final approval, making sure the vision of the designer is fully realized. Once the design is finalized, that’s when the product development starts.

CAD or three-dimensional shop drawings Once the designer has identified and illustrated the concept, a scaled CAD or three-dimensional illustration is created. CKI’s dedicated staff of illustrators create detailed, scaled drawings that include all components of the product down to the last nut, bolt and washer

Metal work and bending It is so important to over see the bending of metal arms for fixed wire lighting and other products. A slight difference in the sweep of a chandelier’s arm can greatly improve or detract from its visual appeal and salability.

Finish specifications The color, texture and luster of a product is crucial to its success. The finish is usually specified in the original concept creation but can change through the development of a product based on a vendor’s strengths and creativity. Cooperation with a vendor is important to find the best possible aesthetic for each piece.

Glass components Most lighting vendors have a large variety of glass components on hand to choose the best fit for the product design, but in many cases, we seek a local glass manufacturer for a more unique, original glass component and finish. A trip to a good glass factory can open a world of creativity and opportunity.

Bill of materials and cost analysis Once you have identified all the components of a product each item must be listed and costed to find the overall cost. In most cases, The factory is responsible for these details, but it is important to cooperate with their staff and adjust as needed to create the best product for the best price.

Prototype sample approval Once all the pieces have been approved and assembled, the designer must approve and sign off on the sample or make whatever minor adjustments are necessary.

Photography The completed approved samples are photographed in high resolution, usually as a part of a vignette and individually.

Show it, sell it, ship it

After the development is complete the products are shown to a wholesale client in a product line review that includes 300-600 new products twice a year. We develop around 5,000 products in an 5 Years period.

Carolyn Kinder International licenses its unique, original product designs to some of the best wholesalers and original equipment manufacturers in the home furnishing industry.

Quality Assurance

Intense competition, seasonality of markets, and continuous demands for innovation create a challenging environment for the manufacturing of bags in India. Quality issues and delivery failures impact directly on your supply chain efficiency, profit margins, and brand’s reputation. Retailers must implement effective quality systems to meet delivery and safety standards, along with the expectations of end users.

CCI offers inspection services at every stage of the supply chain: from selecting new suppliers, through to in-process bag quality control, and final shipment. We examine all types of bag and fashion accessories including handbags, travel bags, backpacks, golf bags, purses, wallets, laptop bags, and more.

CCI verifies the quality, specifications, functions, safety, and compliance of your bags and fashion accessories based on US, EU, and numerous other standards including GB18041, REACH and CPSIA.

ACCESSORIES QUALITY CONTROL APPROACH

CCI technical engineers work closely with your team to design a specific bag or accessory inspection checklist. CCI inspectors verify the quality of mass production based on your Acceptable Quality Limits (AQL), perform product function and safety tests, and assess compliance with your product’s specifications and authorized samples. Your product's workmanship is carefully examined, and defects are classified into subcategories to highlight the key improvement areas for production.

Some tests on bags and accessories require a controlled environment to analyze their compliance with the standards and regulations of your destination country. CCI inspectors can forward samples to an accredited laboratory for testing.

CCI goes above and beyond the average quality inspection service by combining our advanced quality management technology and substantial experience in inspection of bags. We personalize your compliance program, monitor results, and apply corrective actions necessary to support your objectives and achieve lead-times.

Main tests performed during an inspection of bags and accessories

• Fitting test • Color fastness • GSM check

• Flammability • CPSIA • Adhesive test ASTM D3359-02

• Phthalates • Traction tests on accessories ISO 13934, • Fabric weight test / GSM test ISO3801

• Heavy metals • ASTM D5034 • Carton drop test ASTM D5276

• AZO EN14362-1&2 • Appearance after washing • Pilling, Original Sample, Sample after X wash cycle(s)

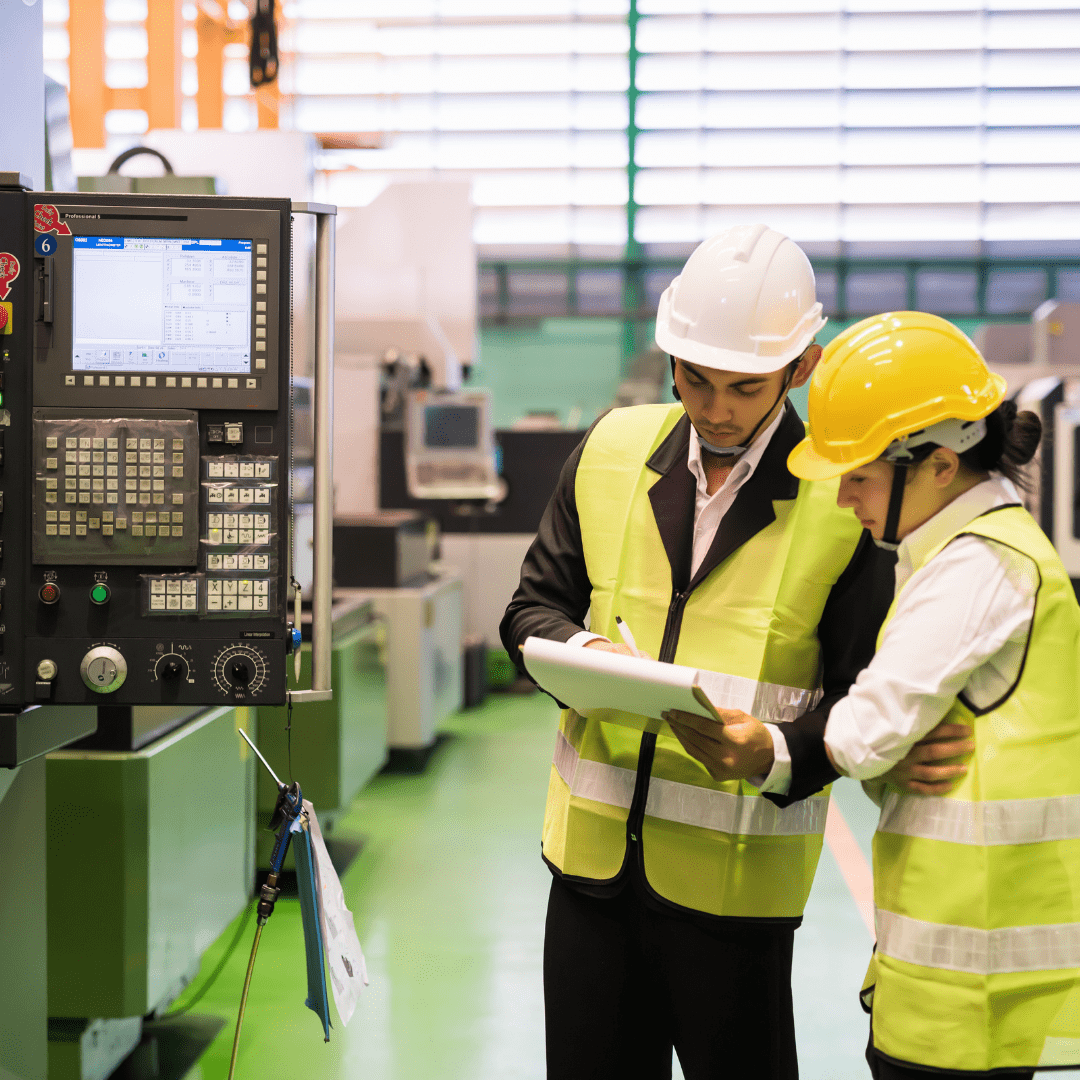

Factory Audit

CCI factory audit services provide you with in-depth, on-site analysis from experienced professionals who understand your expectations and communicate effectively.

CCI professional, accurate and detailed due diligence of suppliers in India is the first step in achieving a solid India supply-chain built on strong partnerships and trust.

Why Audit Your Supplier's Factory?

Suppliers often make bold claims about their facilities, equipment, production capacity, and internal quality control procedures in order to win your business. Typically, the only way to verify such claims is to visit your supplier and observe their capabilities firsthand.

What In Touch Does for You:

CCI’s auditors are dispatched to your selected supplier, with the goal of quantifying their level of professionalism and production capabilities. A detailed report is then submitted for your review, including images of all production, dormitory, meetings, and storage areas of your supplier’s facility.

Furthermore, CCI can investigate a factory’s adherence to ethical standards related to health and safety, employee compensation, illegal labor, and sustainability. CCI’s Ethical Sourcing services are aimed at identifying suppliers that are not only fully capable of producing your goods, but who also place an emphasis on operating within all applicable local laws and international labor standards.

Lab Testing

CCI efficiently manages the testing of samples in liaison with qualified and accredited laboratories according to your requirements, your local market regulations and government standards. With the lab resources integration of our extensive competent laboratories database, for each type of certification, such as CE, EMC, RoHS, REACH, CPSIA, EN71, ASTM, Oeko-Tex etc. We are able to select the best laboratory for client based on both price and lead-time.

WITNESS LAB TESTING AT FACTORY’S LAB

If the supplier or the factory has their own lab but un-accredited. In order to save the cost of lab testing, the client could required the factory do the lab testing at their own lab according the specified standards. The results of lab testing are acceptable only in the condition the whole process of the testing are witnessed by CCI.

Lab Testing capabilities:Our test services cover a wide variety of products and standards, which includes, but it not limited to, the following

Categories include:

- Hardline Products(REACH, ASTM, EN, etc.)

- REACH 53 SVHC Test

- Stainless Steel Material Composition Analysis

- Corrosion Resistant

- Durability Test

- Burning Performance

- Packaging & Transportation Simulating Test

- Construction Materials Test

Third Party Inspection

Logistics

• Forwarder (APLL) for data 850/870/856.

• Customer broker (Carmichael) for data of ISF submission/ISF message/logistic cost.

• Customer (Safeway) for the data of booking ASN/ Shipment ASN/ 880/997/824.

The program works successfully in the past 12 years and been proved the most efficient supply chain solution and management. On top of the great achievement, CCI logistic also implement so called upfront “container loading plan (CLP)” for consolidation program which generate company tremendous logistic saving surplus every year.

WHAT IS CCI CONTAINER LOADING SUPERVISION (CLS)?"

Container Loading Supervision provides reassurance that your finished goods are handled correctly when loaded into containers to ensure safe transportation and delivery to their final destination in a satisfactory condition. Sometimes referred to as Container Loading Inspection, this service usually takes place at the factory or your forwarder's premises and occurs after a pre-shipment inspection (PSI).

CCI Inspectors examine a range of important criteria to ensure accurate quantities of your products are loaded and handled correctly to protect your goods during shipment. We also verify the container is properly sealed and the documentation for customs inspection is available. Each CLS is unique, combining AQF container loading supervision checklists with your unique product specifications and other key criteria.

CCI can arrange Container Loading Supervision in India within 48 hours and guarantee your Container Loading Supervision report and inspection certificate within less than 24 hours.

CCI MAIN CHECKS PERFORMED*

• Container conditions

• Product Specifications

• Shipping Marks, Packaging, & Labelling

• Loading supervision

• Documentation

• Quantity loaded

WHY DO YOU NEED CONTAINER LOADING SUPERVISION?"

• Ensure your products are transported in the appropriate conditions.

• Verify the right goods are loaded into the containers (no substitution).

• Guarantee you receive the total order quantity at the destination.

• Confirm your products are packaged and shipped as per conditions stated on the sales contract.

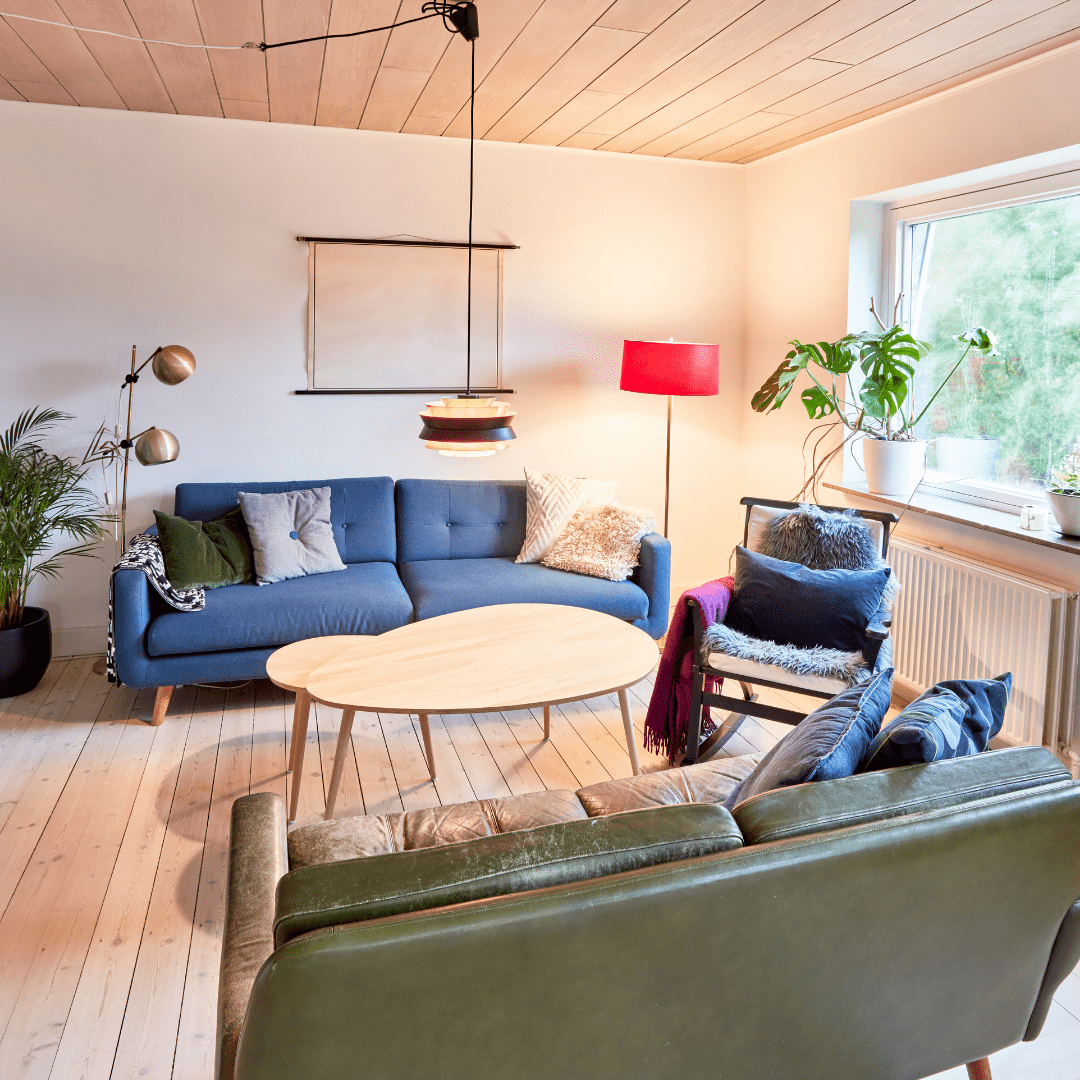

Home & Living

We are on top of the latest trends in both home and lifestyle products, and offer a comprehensive service that covers design, development, sourcing and quality control.

Categories include:

Bathroom

Seasonal

DIY/ hardware

Furniture

Garden décor

Giftware

Glassware

Home décor

Home storage

Home textiles

Housewares

Kitchen appliances

Stationery

Furniture

Furniture is a common feature in our homes and offices and is a reflection of our personal style and economic circumstances. Furniture manufacturing in India poses significant challenges for retailers and e-tailers who must remain innovative while continuing to ensure consumer safety and satisfy demanding time-to-market obligations. Proactive management of furniture quality control is crucial to meeting these challenges and optimizing supply chain performance.

CCI offers furniture inspection services at every stage of the supply chain: from sourcing new suppliers, through to in-process furniture quality control and final shipment. Our expertise includes product categories such as indoor, outdoor, or contractual furniture made of wood, plastic, metal.

CCI verifies the quality, specifications, functions, safety, and compliance of your furniture with relevant standards. We check compliance based on US, EU, and dozens of other specific standards including ISO, EN 581 for outdoor furniture; EN1728& EN22520 for domestic furniture; EN-1335 & BIFMA for office furniture, EN 71 for Children furniture.

CCI technical engineers, work hand in hand with your team to understand key risks. This ensures the CCI product-specific Furniture inspection checklist is fully customized to your needs.

CCI inspectors verify the quality of mass production based on your Acceptable Quality Limits (AQL), perform product function and safety tests, and assess compliance with your product’s specifications and authorized samples. We also check the suitability of packaging to protect your furniture, marking, instruction manuals, accessories, and barcodes.

Some tests on furniture require a controlled environment to ensure compliance with applicable safety standards and regulatory requirements. CCI inspectors select production samples and forward them to an accredited laboratory for testing.

CCI provides value-added services to improve the efficiency of your quality control in India. We use our expertise in furniture inspection and leading edge quality management software to support you and your suppliers. We set up, monitor, and optimize your quality control program to achieve your quality objectives and lead-times.

Main tests performed during an inspection of furniture:

• Performance • Stability check • Accessories

• check • Moisture • check

• Size • content • Packing

• measurement • Rub test on • Export carton

• Material & color • fabric • drop test

• check • Fatigue test • Shear & press

• Adhesive test on • Wobbly base • Point check

• logo • test • Cap removal

• Static loading • Smell test • strength

• test • Assembly check

• Hole, tubular

• components

• and fixed gaps

• check

Furniture testing in a laboratory:

• BS EN 581

• NF D 60-300-2

• EN 71

• for Children furniture etc

• EN-1335 & BIFMA

• for office furniture

• EN1728& EN22520

• for domestic furniture

Lighting

Achieve new levels of energy efficiency through intelligent lighting control. Our connected lighting systems use knowledge of the illuminated space to deliver the right level of light in the right place at the right time.Create amazing new lighting experience, from transforming an iconic landmark with dynamic full-color light, to enabling the lights in your home to flash your team’s colors when they score,

Categories include:

Table Lamps

Floor Lamps

Wall Lamps

Pendants

Fashion Accessories

Intense competition, seasonality of markets, and continuous demands for innovation create a challenging environment for the manufacturing of bags in India. Quality issues and delivery failures impact directly on your supply chain efficiency, profit margins, and brand’s reputation. Retailers must implement effective quality systems to meet delivery and safety standards, along with the expectations of end users.

CCI offers inspection services at every stage of the supply chain: from selecting new suppliers, through to in-process bag quality control, and final shipment. We examine all types of bag and fashion accessories including handbags, travel bags, backpacks, golf bags, purses, wallets, laptop bags, and more.

CCI verifies the quality, specifications, functions, safety, and compliance of your bags and fashion accessories based on US, EU, and numerous other standards including GB18041, REACH and CPSIA.

ACCESSORIES QUALITY CONTROL APPROACH :

CCI technical engineers work closely with your team to design a specific bag or accessory inspection checklist. CCI inspectors verify the quality of mass production based on your Acceptable Quality Limits (AQL), perform product function and safety tests, and assess compliance with your product’s specifications and authorized samples. Your products’ workmanship is carefully examined, and defects are classified into subcategories to highlight the key improvement areas for production. Some tests on bags and accessories require a controlled environment to analyze their compliance with the standards and regulations of your destination country. CCI inspectors can forward samples to an accredited laboratory for testing. CCI goes above and beyond the average quality inspection service by combining our advanced quality management technology and substantial experience in inspection of bags. We personalize your compliance program, monitor results, and apply corrective actions necessary to support your objectives and achieve lead-times.

Main tests performed during an inspection of bags and accessories:

• Fitting test • Color fastness • GSM check

• Functions • test • Loading test

• check • Smell test • • Abuse/fatigue

• Pull test on • Metal detection • test

• seam • test • Export carton

• Adhesive test • Stitches per inch • drop test

• on logo and • check

• label • Inside stuffing

• check

Bags and Accessories testing in a laboratory:

• Azo • Hydrostatic • Seam Strength

• Carcinogenic • Pressure Test • Tearing

• Allergenic Dyes • Oil Repellency • Strength

• Extractable • Tensile strength • test

• Heavy Metals • verification • Zipper strength

• Water • Laundering test • Fiber

• Resistance • Dry clean • composition

• Water • Hand wash • test

• Repellency • Pilling, Original • REACH

• (Spray Test) • Sample • CPSIA

• Color fastness • Sample after X • Proposition 65

• test • wash cycle(s)

Apparel

Customers’ expectations are high in the textile and garment industry. Any quality issue, price discrepancy, or late delivery directly affects your business finances and reputation. Retailers involved in textile and garment manufacturing in India must optimize the entire supply chain to stay competitive, meet delivery deadlines, and build an environmentally and socially responsible business.

CCI offers inspection services in India for all kinds of garments and home textiles such as shirts, jeans, jackets, underwear, sleepwear, workwear, gloves, knit hats, socks, belts, scarves, aprons, and blankets.

We verify your textile and garment quality, specifications, functions, safety, and compliance with relevant applicable standards: US, EU, and numerous other standards including ISO, AATC, EDANA, ASTM.

TEXTILES AND GARMENTS QUALITY CONTROL APPROACH

Each inspection is customized by combining our standard AQF garments inspection checklists with your unique product specifications. We verify the quality of mass production based on your Acceptable Quality Limits (AQL), identifying and classifying defects to offer an overview of your product’s quality. We also perform on-site tests and assess compliance to your product’s specification and approval sample. Checks include sizing, measurements, labeling, packaging, and packing.

Some textiles and garments tests require a controlled environment to certify their compliance with the applicable standards and regulations. CCI inspectors select products from the factory and send them to an accredited laboratory to have these tests performed.

CCI can add even more value to your quality control processes. Based on our textile and garment expertise, we set up and execute a customized inspection procedure, monitor the results, and help you implement the necessary corrective actions to reach your quality objectives and lead-times.

Main tests performed during an inspection of Textiles and Garments

• Smell test • GSM test • Metal/needle detection test

• Fitting test • Adhesive test • Stuffing material check

• Symmetry check • Abuse test • Barcode scanning

• Color fastness test • Seam strength test • Carton drop test

Garments testing in a laboratory

• Color fastness • REACH • Care label verification

• Flammability • CPSIA • Adhesive test ASTM D3359-02

• Phthalates • Traction tests on accessories ISO 13934, • Fabric weight test / GSM test ISO3801

• Heavy metals • ASTM D5034 • Carton drop test ASTM D5276

• AZO EN14362-1&2 • Appearance after washing • Pilling, Original Sample, Sample after X wash cycle(s)

Why Us

Complete 360° Management

We produced the 360 ° Portal with the intent of aiding e-commerce professionals browse the sourcing industry extra easily, allowing you to check out and also manage all aspects of your business in one place.

Our Portal takes the inconveniences, info delays, and also frustrations out of collaborating your sourcing-- completely from discovering a supplier to placing the items at your stockroom's door.

PROJECT VIEW

DOCUMENT DOWNLOAD

STATUS UPDATES

KEY DATES

Easy as 1, 2, 3

Establish Contact

Client fills up the questions type and also receives a call or e-mail from the sales team

Requirement Analysis

Need evaluation, Ballpark price quote, Go-ahead Approval, Execute pilot project

Pricing & Contracting

Confirm prices, Proposal where required, Contracting & SLA sign-off

Project Initiation

Resource deployment & Training, Project kick-off meeting

Project Steady State

1.2.3.

From Our Founder

Make Your Own Opportunities

At Asiasourcing, we have the experience as well as ability to handle every element of your outsourcing venture. We promise that you will certainly begin to enjoy the flexibility to concentrate on constructing your company, while we effectively handle your task and also deliver your back office requirements.

It went beyond todays search engine inventories, it was an idea that enabled wide range creation for global clients. It was an idea that harnessed the climbing workforce skill in establishing economic situations and cultivated them as employees-at-large to established countries at a cost-effective scale!

At Asiasourcing, we have the experience and ability to take care of every element of your outsourcing endeavour. Obtain every concern answered, validate every case, visit our delivery facilities and also learn concerning the advantages of working with Asiasourcing. We guarantee that you will start to take pleasure in the liberty to concentrate on building your service, while we effectively manage your task as well as deliver your back workplace needs.

CCI is our 'eyes-and-ears' in India – providing highly technical and professional inspection services, coupled with quick response times and experienced reliability. Their highly skilled sourcing & inspection teams allow us to deliver flawless products to our clients, time after time.

Testimonials

We have been working with CCI for Sourcing In India since 2010. Now CCI is the sole agency for our quality control in India. CCI inspections reduce concerns about quality control issues and I recommend CCI Inspection to any company importing from India. Compared to other large QC companies we have used, we get better inspection services while cutting our QC budget by 50%.

For two years, CCI has helped us solve quality issues and we' re very satisfied. CCI is the partner we need. Its pro-active team has proved very efficient and the quality of their reports is amazing. Its service allows us to prevent problems before they occur and keep our customers informed.

Set Up a Free Consultation Today!

Moradabad 244001 India

+91-591-7960251

+91 9837035222

[email protected]